Direct Answer: Crucial Restrictions for Nitrile Use While nitrile gloves are the gold standard for many industries, you should not wear them when working with open flames, handling highly oxidizing acids, or operating r...

READ MORE-

-

Direct Verdict: The Safety Profile of Nitrile Foam To answer the question directly: Yes, nitrile foam is exceptionally safe for the vast majority of people and is often the preferred choice for those with sensitive skin...

READ MORE -

The Definitive Superiority of Nitrile Gloves The primary factor that makes nitrile gloves special is their unmatched combination of chemical resistance, puncture durability, and hypoallergenic properties compared to lat...

READ MORE

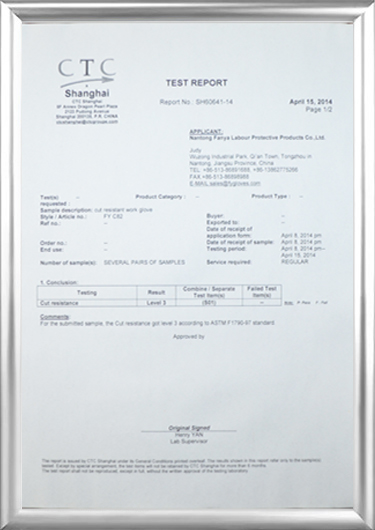

In modern industry and occupational safety, cut resistant gloves, as a core component of protective equipment, play a vital role. Jiangsu Fanya Labour Protective Products Co., Ltd., a professional manufacturer adhering to a "people-oriented" principle, is committed to providing high-quality protective solutions through long-term partnerships with domestic and international companies.

Question 1: What is the basic definition of cut resistant gloves?

Answer:

Cut resistant gloves are a type of personal protective equipment specifically designed to protect hands from cuts or punctures from sharp objects during work.

These gloves, designed with specialized materials and structures, provide a physical barrier against external impacts.

They are an indispensable protective tool in occupational safety systems, especially in high-risk environments.

Based on its "people-oriented" philosophy, Jiangsu Fanya Labour Protective Products Co., Ltd. focuses on developing these gloves, ensuring that our products not only meet basic protective needs but also take into account the long-term health of users.

Question 2: What key technologies are involved in the protective mechanism of cut resistant gloves?

Answer:

The protective mechanism primarily relies on the use of high-performance fibers, such as aramid fibers and ultra-high-strength polymers, which enhance cut resistance through tightly woven or layered structures.

The glove's design incorporates impact dissipation mechanisms. When a sharp object contacts the surface, the material absorbs and dissipates the energy, reducing the risk of penetration.

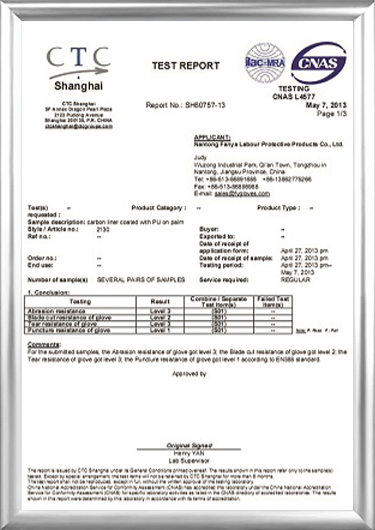

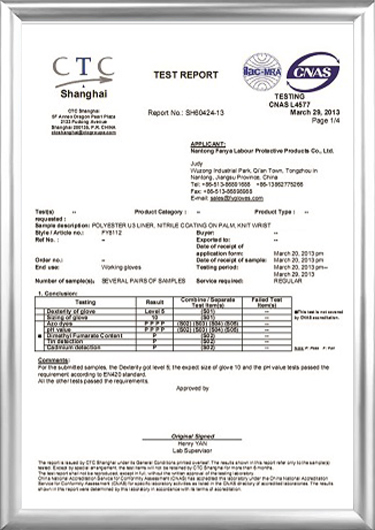

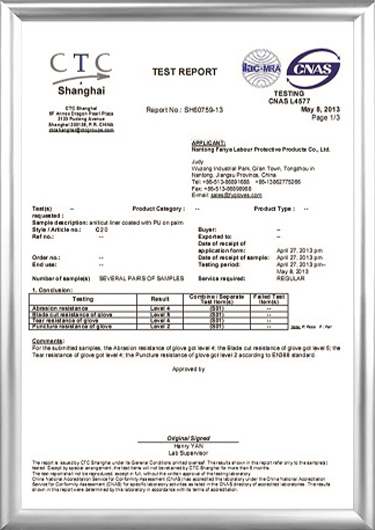

Protection levels are typically classified according to international standards, with different levels corresponding to different risk scenarios, ensuring users select the appropriate product for their specific working conditions.

Jiangsu Fanya Labour Protective Products Co., Ltd. incorporates a human-centric approach into its technological research and development, optimizing fiber combinations and manufacturing processes to enhance the overall performance and durability of its gloves.

Question 3: In which industries and applications are cut resistant gloves essential?

Answer:

Manufacturing is a core application area, particularly in metalworking, glass cutting, or mechanical assembly, where gloves effectively protect operators from sharp fragments.

In food processing industries, such as meat processing or kitchen work, these gloves can prevent accidental cuts caused by knives. Construction and maintenance work involving saw blades, nails, or other sharp instruments requires cut resistant gloves to ensure worker safety.

This type of protection is also required in medical and laboratory environments to reduce occupational risks when handling syringes or laboratory instruments.

Jiangsu Fanya Labour Protective Products Co., Ltd. provides customized solutions for various industries through long-term collaborations, emphasizing a people-centric approach to ensure gloves are suitable for different work needs.

Question 4: How to evaluate and select high-quality cut resistant gloves?

Answer:

The evaluation process prioritizes the risk level of the work. Gloves with the appropriate protection level should be selected for high-risk cut situations.

Material selection is crucial, balancing protection, comfort, and dexterity to avoid glove stiffness that can hinder operation.

Glove certification compliance must be verified to ensure compliance with industry standards and reliable barrier performance.

Durability and ease of maintenance during long-term use are also key factors. Regular inspections of the gloves can extend their lifespan.

Jiangsu Fanya Labour Protective Products Co., Ltd. prioritizes comfort and safety in design and production, helping customers make informed choices.

Question 5: How does Jiangsu Fanya Labour Protective Products Co., Ltd. enhance the value of its Cut Resistant Gloves through a "people-centric" approach?

Answer:

Adhering to a "people-centric" principle, the company prioritizes employee health and well-being. The gloves it develops focus on ergonomic design to reduce fatigue after prolonged wear.

By establishing long-term partnerships with domestic and international companies, we continuously collect user feedback and iterate our products to meet actual needs, ensuring maximum protection.

Innovative technologies are incorporated into the manufacturing process, such as the use of hypoallergenic materials and breathable structures, to enhance wearer comfort without sacrificing protective performance.

Emphasized as a comprehensive protection concept, we offer a range of products from basic to advanced, enabling users in different roles to receive customized safety solutions.

This people-centric approach not only enhances the practicality of the gloves but also promotes the improvement of overall industry safety standards.

中文简体

中文简体