Direct Answer: Crucial Restrictions for Nitrile Use While nitrile gloves are the gold standard for many industries, you should not wear them when working with open flames, handling highly oxidizing acids, or operating r...

READ MORE-

-

Direct Verdict: The Safety Profile of Nitrile Foam To answer the question directly: Yes, nitrile foam is exceptionally safe for the vast majority of people and is often the preferred choice for those with sensitive skin...

READ MORE -

The Definitive Superiority of Nitrile Gloves The primary factor that makes nitrile gloves special is their unmatched combination of chemical resistance, puncture durability, and hypoallergenic properties compared to lat...

READ MORE

Are you curious about the core properties of PU coated gloves and their importance in modern industry? As a key component of professional protective equipment, PU coated gloves are widely used in various fields due to their unique properties.

What are the basic components and material properties of PU coated gloves?

PU coating, or polyurethane coating, is a high-performance synthetic material that is applied to the surface of a glove base (such as knitted cotton or nylon) to form a soft and durable protective layer. This material exhibits excellent elasticity and conformability, effectively enhancing the comfort and dexterity of the gloves. Polyurethane is inherently chemically inert and resistant to oils, solvents, and weak acids and bases, while providing high grip and reducing the risk of slippage during work. Jiangsu Fanya Labour Protective Products Co., Ltd. utilizes its automated production lines to precisely control coating thickness and uniformity, ensuring maximum material properties. The company's technological environment supports precise material mixing, eliminating batch variations associated with traditional processes, thereby maintaining product consistency and reliability.

What are the core functional advantages and application areas?

The core value of these gloves lies in balancing protection with ease of use. Its key features include anti-slip, abrasion resistance, puncture resistance, and moderate chemical resistance, making it suitable for delicate operations such as electronic assembly, automotive repair, medical cleaning, and food processing. The PU coating provides a stable grip in both wet and dry environments, reducing the risk of repetitive strain injuries. Jiangsu Fanya Labour Protective Products Co., Ltd. utilizes an automated conveyor system to efficiently cure the coating during its production process, optimizing the glove's feel and durability. The company's real-time quality monitoring mechanism dynamically tracks coating adhesion and surface texture, ensuring that each pair of gloves maintains functional integrity in complex applications and seamlessly adapts to various industrial needs.

What is the decisive influence of manufacturing processes on product performance?

The manufacturing of PU coated gloves involves key steps such as coating formulation, substrate pretreatment, and curing. Coating thickness and distribution directly impact the glove's dexterity and protective level. Coatings that are too thin or too thick can result in performance defects. Jiangsu Fanya Labour Protective Products Co., Ltd.'s factory utilizes a fully automated production line, enabling continuous operations from dipping to drying, reducing variables caused by human intervention. Automated systems ensure uniform coating coverage and use high-precision sensors to monitor parameters such as temperature and humidity in real time to prevent bubbles or cracks. This high-tech production environment not only improves efficiency but also significantly enhances the product's structural stability and lifespan.

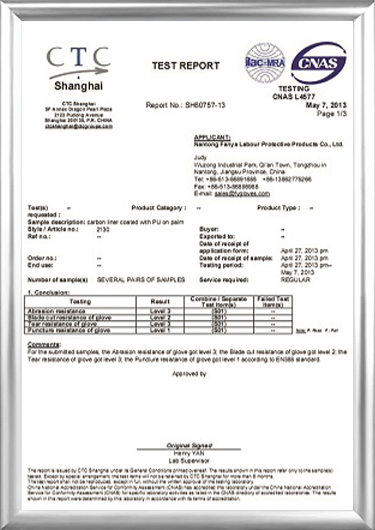

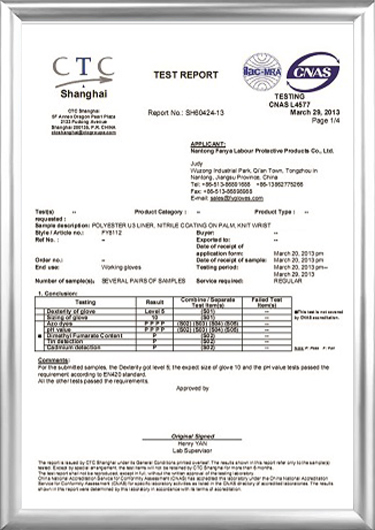

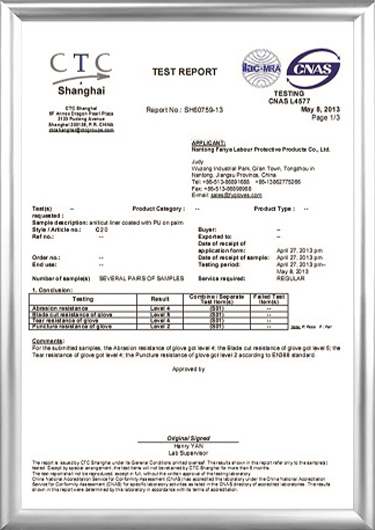

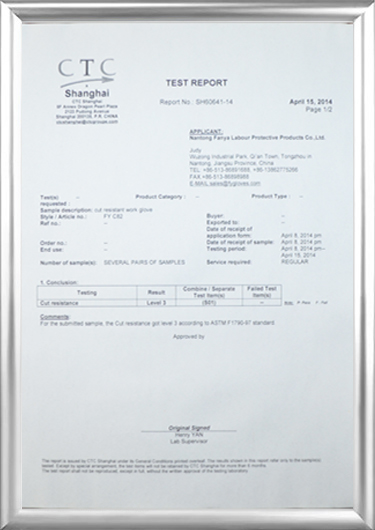

Is quality control and compliance with industry standards important?

Quality control is central to the production of PU coated gloves, ensuring they meet common performance requirements such as tensile strength, weather resistance, and biocompatibility. Jiangsu Fanya Labour Protective Products Co., Ltd. demonstrates a leading advantage in this area. Its automated monitoring system instantly identifies coating or substrate defects and automatically triggers adjustments. The company's high-tech production environment integrates visual inspection and data analysis tools to ensure consistent quality for each batch of gloves before shipment. This seamless quality assurance system ensures its products reliably meet the stringent international market expectations for protective equipment, solidifying the company's expertise in the labor protection products industry.

What are the industry trends and sustainability considerations?

PU coated gloves are evolving towards environmental friendliness and multifunctionality, with a focus on incorporating biodegradable materials and hypoallergenic designs. Jiangsu Fanya Labour Protective Products Co., Ltd.'s production practices reflect this trend. Its automated platform supports efficient resource utilization and reduces waste. Through intelligent systems, the company optimizes energy and raw material consumption, promotes green manufacturing, and ensures high-performance and environmentally friendly products throughout their lifecycle. This reflects the modern labor protection products industry's pursuit of a fusion of innovation and responsibility.

中文简体

中文简体