Art.No.:FY.5151

Standard:3131X

Application:

1. Assembly

2. General maintenance

3. Gardening

4. Assembly

Art.No.:FY.5151

Standard:3131X

Application:

1. Assembly

2. General maintenance

3. Gardening

4. Assembly

Direct Answer: Crucial Restrictions for Nitrile Use While nitrile gloves are the gold standard for many industries, you should not wear them when working with open flames, handlin...

READ MOREDirect Verdict: The Safety Profile of Nitrile Foam To answer the question directly: Yes, nitrile foam is exceptionally safe for the vast majority of people and is often the prefer...

READ MOREThe Definitive Superiority of Nitrile Gloves The primary factor that makes nitrile gloves special is their unmatched combination of chemical resistance, puncture durability, and h...

READ MORENitrile gloves are gloves made from synthetic rubber. They don't tear easily like ordinary plastic gloves, nor do they cause skin allergies like old-fashioned rubber gloves.You can...

READ MOREThe "PU" in PU gloves refers to polyurethane, the material used. If you see gloves in a store with a thin coating on the palm that looks somewhat like plastic or artificial leather...

READ MORENitrile coated gloves have become a widely used solution in industrial safety and personal protection. Their unique performance and reliable protection have earned them the trust of numerous industries.

1. What is the basic definition and core component of Nitrile coated gloves?

Answer:

These gloves utilize a nitrile rubber coating over a base glove material, creating a composite protective structure that provides an additional barrier function.

Nitrile, a synthetic rubber material, is derived from the polymerization of acrylonitrile and butadiene, resulting in high chemical stability and physical toughness.

Jiangsu Fanya Labour Protective Products Co., Ltd., a company long-term dedicated to the production of labor protection products, prioritizes the use of high-quality raw materials in the manufacture of these gloves, ensuring uniform coating adhesion and optimizing overall protective performance.

The core component is designed to balance flexibility and protective strength, avoiding allergic reactions common with natural rubber, making it suitable for all skin types.

2. What are the main advantages and features of Nitrile coated gloves?

Answer:

The excellent chemical resistance allows them to resist a variety of industrial solvents, oils, acids, and bases, preventing penetration and corrosion, and extending the life of the gloves. Outstanding physical durability is demonstrated by puncture, tear, and abrasion resistance, making them particularly suitable for high-intensity work environments such as mechanical operation or heavy lifting.

The excellent fit and comfort are due to the thin coating design, which reduces hand fatigue and enhances the wearing experience. Manufacturers such as Jiangsu Fanya Labour Protective Products Co., Ltd. frequently optimize production processes to ensure consistent coating thickness for a seamless fit.

Environmental and safety features include the absence of lactoglobulin, eliminating the risk of allergies. The coating material is also recyclable, aligning with modern sustainable production concepts.

3. What industries are Nitrile coated gloves typically used in?

Answer:

In the manufacturing sector, these gloves are widely used in automotive assembly, electronic component handling, and metal processing, providing oil and slip resistance.

In chemical and laboratory environments, their solvent resistance makes them an excellent choice for handling chemicals or biological samples, ensuring that operators are protected from harmful substances. In cleaning and maintenance work, such as sanitation or food processing, gloves' waterproof and easy-to-clean properties simplify routine maintenance. Jiangsu Fanya Labour Protective Products Co., Ltd.'s products are frequently used in these settings, thanks to its rigorous quality control system.

Medical and emergency medical applications are also included, particularly in non-sterile procedures, where they provide basic protection and enhanced grip.

4. What are the key considerations for choosing Nitrile coated gloves?

Answer:

Long-term economic benefits stem from their durability and potential for reuse, which reduces the cost of frequent replacements. Furthermore, suppliers like Jiangsu Fanya Labour Protective Products Co., Ltd. ensure cost-effectiveness through large-scale production.

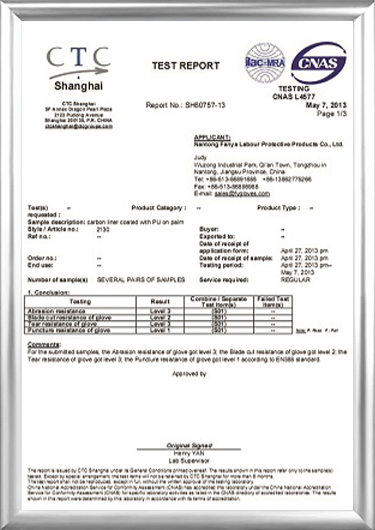

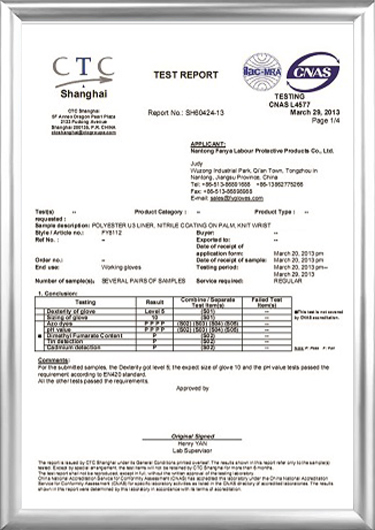

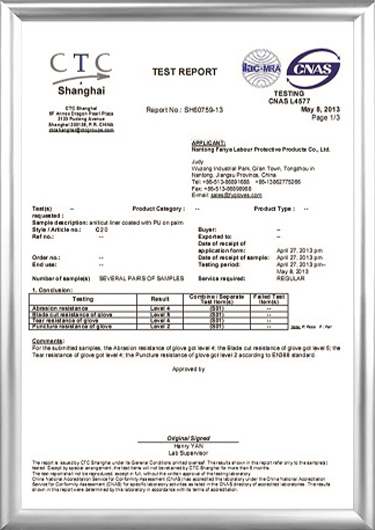

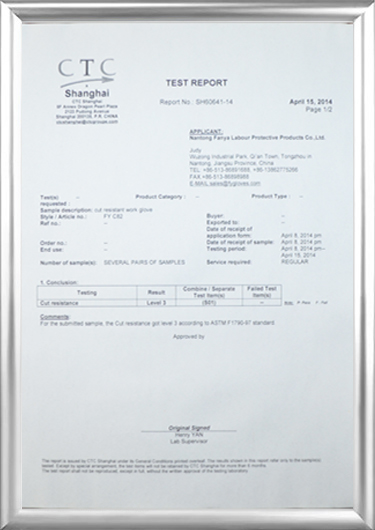

Safety and compliance are reflected in the gloves' compliance with international protection standards, eliminating regulatory conflicts. Manufacturers ensure batch-to-batch consistency through internal control processes.

Versatile adaptability enables them to handle temperature and humidity fluctuations and oily environments, making them more flexible than other coated gloves. Professional manufacturers continuously improve their environmental adaptability through research and development.

User-friendly designs include breathable textures and grip-enhancing surfaces. Jiangsu Fanya Labour Protective Products Co., Ltd. prioritizes ergonomic testing during development to optimize the user experience.

5. What role do manufacturers like Jiangsu Fanya Labour Protective Products Co., Ltd. play in the production of Nitrile coated gloves?

Answer:

As an industry leader, Jiangsu Fanya Labour Protective Products Co., Ltd. specializes in the research and development and production of labor protection products. Its extensive experience ensures comprehensive quality control of gloves, from raw materials to finished products.

The production process emphasizes efficiency and environmental protection, utilizing advanced coating technology to achieve uniform coating distribution, enhancing product reliability and protective effectiveness.

Market responsiveness is reflected in its ability to quickly adapt to changing global demand. For example, with its export-oriented business model, the company prioritizes ensuring its products adhere to international protective trends.

Driven by innovation, Jiangsu Fanya Labour Protective Products Co., Ltd. continuously optimizes glove formulations and processes to provide users with cutting-edge protective solutions.